-

Single layer tile press series

-

Double layer tile press series

-

Three layer tile press series

-

Floor bearing plate equipment

-

Glazed tile equipment series

-

Jiaochi equipment series

-

C/z/u-shaped steel forming mac

-

Carriage plate forming machine

-

Anti skid embossing equipment

-

Aluminum magnesium manganese 4

-

Ridge tile forming machine ser

-

Light steel keel machine serie

-

Shearing machine bending machi

-

Rock wool foam integrated sand

-

Rolling shutter door equipment

-

Discharge rack series of hydra

-

Export equipment series

-

Kaiping machine series

-

pipe benders

-

Customize cold bending equipme

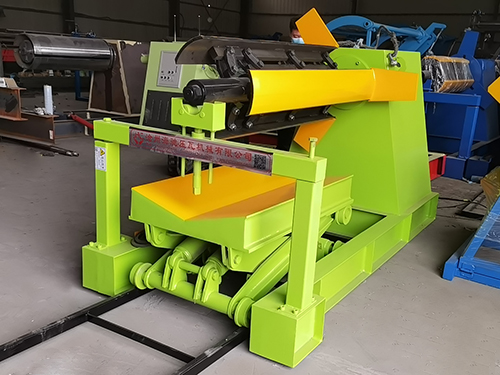

Hydraulic uncoiler products

Hydraulic uncoiler is a metal plate leveling equipment, which is used for leveling line. Steel plates and uneven plates can form uncoiling, leveling, shearing production lines and other plate product production lines according to relevant configurations. Applicable to machinery, vehicles, metal products, household appliances, steel structures, decoration and other industries

hydraulic uncoiler is one of the important equipment in welded pipe production line. One of its functions is to support the steel coil by tightening the inner hole of the steel coil; The other is to feed the steel part into the leveler through rotation with the cooperation of the straightener. Therefore, the performance of the winder is very important to the whole production line. In the design practice, the structure of the winder has been continuously optimized and improved, so that the performance of the winder has been improved

the main shaft of the hydraulic uncoiler has two functions: one is to drive the steel coil to rotate; The other is the tension support of steel coil. The realization of tightening is usually completed by the oil cylinder or cylinder installed with the main shaft to push the inclined slider. The small unit uses more cylinders, and the large unit uses more cylinders; Rotation is usually achieved by the motor driving the spindle to rotate through the reducer. The oil cylinder or cylinder installed on the main shaft should rotate with the main shaft, and the oil cylinder or cylinder should be connected with one end of the working medium pipeline, and the other end of the pipeline should be connected to the hydraulic station or solenoid valve

hydraulic uncoiler shall be strictly in accordance with " Operating procedures of winder " Operate

1. During the feeding operation, a special person should cooperate with the forklift driver to make the steel coil material basically consistent with the center of the expansion and contraction drum shaft, and then the forklift driver slowly puts the steel coil material on the trolley

2. The operator should raise or lower (lifting trolley), adjust the steel coil material to the center of the expansion and contraction drum shaft (that is, the material can enter the expansion and contraction shaft), at this time, adjust the movable bearing seat of the winder to keep it at the same level with the winder

3. Adjust the expansion nut to make four arc plates and expand the steel coil material to avoid deformation and damage of the steel coil material during work

4. After the steel coil material is tightened, turn the winder by hand to observe whether the material rotates freely, so as to avoid various hidden dangers in the work