-

Single layer tile press series

-

Double layer tile press series

-

Three layer tile press series

-

Floor bearing plate equipment

-

Glazed tile equipment series

-

Jiaochi equipment series

-

C/z/u-shaped steel forming mac

-

Carriage plate forming machine

-

Anti skid embossing equipment

-

Aluminum magnesium manganese 4

-

Ridge tile forming machine ser

-

Light steel keel machine serie

-

Shearing machine bending machi

-

Rock wool foam integrated sand

-

Rolling shutter door equipment

-

Discharge rack series of hydra

-

Export equipment series

-

Kaiping machine series

-

pipe benders

-

Customize cold bending equipme

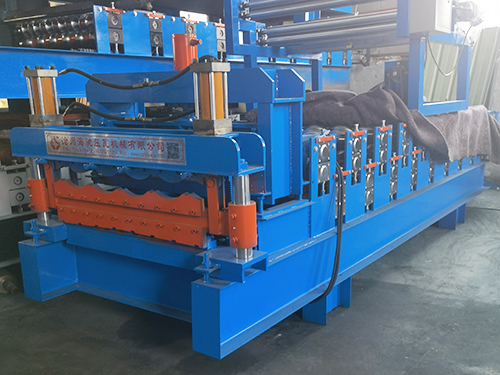

910-828 double layer tile press

910-828 double-layer tile press uses galvanized steel plate or colored steel plate or aluminum plate of different colors as raw materials. The products produced are used to build the external roof and wall plates and internal decorative plates or ceilings of houses, so as to increase the beauty of roofs or walls. 910-828 double-layer tile press has no limit on the production length. It can set multiple groups of different data on the computer controller according to the construction requirements. After one key "confirm", the equipment will automatically produce finished products of different lengths according to the data set by the computer. The finished surface produced by the glazed tile press production line is flat, smooth, flat, and free of scratches, which is convenient for construction and installation

910-828 double-layer tile press adopts a new hydraulic cutting system, which includes forming host, hydraulic station, discharge rack, forming shear, control box and discharge rack

the antique glazed tiles formed by the roll stamping die of 910-828 double-layer tile press have the characteristics of beautiful appearance, simplicity and elegance, exquisite and chic shape, excellent grade and so on. They can be widely used in garden factories, tourist scenic spots, pavilions and pavilions, hotel villas, exhibition halls, resorts, homes and other buildings and outdoor decoration

910-828 double-layer tile press before use, check whether the connections are secure, whether the mounting bolts and nuts are tightened, and add enough lubricating oil in the left and right chassis before powering on and starting the machine for commissioning. First, operate the machine empty and carefully observe whether there is vibration, noise, oil coming from the oil window, whether the movements of all parts are coordinated, and whether the diversity is normal before installing the mold. When installing the mold, cut off the power supply, Manually move the motor belt or big gear to rotate the workbench and raise the sliding seat to the high point, so that an object can be supported between the workbench and the bottom surface of the sliding seat to prevent the sliding seat from falling naturally, causing an accident. The mold used by this machine requires an upper mold and six lower molds with the same specification and size. First, install the upper mold and a lower mold. The lower mold is directly installed on the hexagonal runner workbench, and the upper mold is installed on the bottom surface of the sliding seat, with a suitable thickness of backing plate placed. After the upper and lower molds are closed, the gap around them is uniform, and the distance between the upper and lower molds is equal to the thickness of the required tile blank. Then, the upper mold shall prevail, the workbench shall be rotated, and the remaining five sets of lower molds shall be installed. After all the upper and lower molds are installed, the tile pressing can be started

910-828 double-layer tile press technical parameters:

overall dimension of feeding rack: 5800mm long × 1350mm wide × 1200mm high

the maximum speed of the forming machine: 6m/min

the thickness of the formed color steel plate: 0.5-0.8mm

the expanded width of the formed color steel plate: 1000mm

the width of the formed glazed tile: 828mm, deviation ± 1/100

the wave height of the formed glazed tile: 28mm, deviation 28-0.3

roll shaft diameter: Φ 70mm

computer operation panel, text screen