-

Single layer tile press series

-

Double layer tile press series

-

Three layer tile press series

-

Floor bearing plate equipment

-

Glazed tile equipment series

-

Jiaochi equipment series

-

C/z/u-shaped steel forming mac

-

Carriage plate forming machine

-

Anti skid embossing equipment

-

Aluminum magnesium manganese 4

-

Ridge tile forming machine ser

-

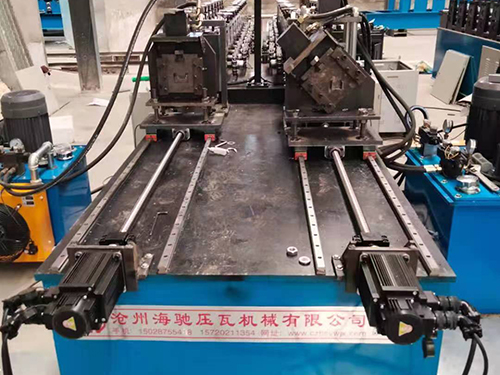

Light steel keel machine serie

-

Shearing machine bending machi

-

Rock wool foam integrated sand

-

Rolling shutter door equipment

-

Discharge rack series of hydra

-

Export equipment series

-

Kaiping machine series

-

pipe benders

-

Customize cold bending equipme

Light steel keel machine

Light steel keel machine is a single roll forming unit that can produce purlin products of various specifications. It is mainly composed of leveling device, passive loading frame, post forming cutting device, punching device, hydraulic station, computer control system, etc. It is the main material for making light steel structure, which is made of steel plate or steel strip by cold bending

before starting the light steel keel machine, add an appropriate amount of lubricating oil to do a good job of lubrication. In addition, the light steel keel machine should also regularly check the handle, keys, V-belts and other parts to see if there is serious damage. Secondly, when the light steel keel machine is operated, it shall be operated according to the formal instructions, and the man-machine integration shall be achieved during the operation. Non technical operators are forbidden to operate the machine. Thirdly, the light steel keel machine should be cleaned regularly to keep it clean. At the same time, the light steel keel machine also needs to check whether the operation of electrical appliances is normal. If there is a problem, the power supply of the machine should be turned off in time for maintenance and inspection. Then, when the machine stops running, clean the light steel keel machine and check the components to see if they need lubrication

maintenance matters of light steel keel machine:

I. add lubricating oil before starting the light steel keel machine every time to do a good job of lubrication

II. The light steel keel machine should also regularly check the handle, keys, V-belts and other parts to see if there is serious damage

III. when operating the light steel keel machine, operate according to the formal instructions, and achieve man-machine integration during operation. Non technical operators are forbidden to operate the machine

IV. the light steel keel machine should be cleaned regularly to keep it clean

v. the light steel keel machine also needs to check whether the operation of electrical appliances is normal. If there is a problem, the power supply of the machine should be turned off in time for maintenance and inspection

VI. when the machine stops running, clean the light steel keel machine and check the parts to see whether the light steel keel machine needs lubrication

several simple installation methods of light steel keel machine:

first, C-type light steel keel without additional load is adopted, which is mainly the main keel of ceiling with single-layer structure. Generally, we will link it with suspenders or light hangers, and hook both sides of the notch of C-type keel at the lower end

II. The T-shaped main keel is a portable ceiling. We generally use the supporting T-shaped keel hanger, the upper part is not connected to the upper hanger, and the lower part clamps the T-shaped keel hanger. In particular, the galvanized iron wire hanger passes through the eyelet on the keel to hook and bind

III. for the ceiling load-bearing keel with additional load, the load-bearing keel hanger can be connected with the threaded part at the lower end of the reinforcement suspender, and the nut can be tightened and clamped firmly

the interface of the light steel keel machine is fixed with T-shaped keel connectors. The secondary keel and the main keel are connected by plug-in, and no accessories are required. If the ceiling has additional load or a large area of ceiling, a U-shaped bearing keel is required, that is, after the suspender is installed, the U-shaped main keel is connected with the suspender with a U-shaped bearing keel (main keel) hanger, and then the T-shaped longitudinal keel is connected with the U-shaped main keel with a T-shaped keel hanger

after the operation of the light steel keel machine is checked before starting up, during the operation of the machine, the temperature and operation of the machine should be strictly controlled. During the operation, whether there is instability, whether there is grinding of the machine, and whether there will be a strong sound. If there is, it is necessary to stop the machine immediately for inspection. After the light steel keel machine has been running for a period of time and used for a period of time, The machine should be lubricated and cleaned regularly. The machine is clean and easy to operate. The aged parts should be replaced in time

generally speaking, the light steel keel machine is made of continuous cold rolling of strip steel. Production of complex profiles (products include: light steel keel, paint keel, clip keel, various building profiles, steel structures, steel lined door frame profiles, guardrails, etc.) And according to customer requirements, we plan and manufacture different specifications of cold bending and paint baking units. The light steel keel produced by the light steel keel machine is easy to install and flexible. It is equipped with dozens of colors, which makes the color matching effect special, and is suitable for all kinds of architectural decoration; Suitable for indoor use in bedrooms, kitchens, bathrooms, corridors, etc