-

Single layer tile press series

-

Double layer tile press series

-

Three layer tile press series

-

Floor bearing plate equipment

-

Glazed tile equipment series

-

Jiaochi equipment series

-

C/z/u-shaped steel forming mac

-

Carriage plate forming machine

-

Anti skid embossing equipment

-

Aluminum magnesium manganese 4

-

Ridge tile forming machine ser

-

Light steel keel machine serie

-

Shearing machine bending machi

-

Rock wool foam integrated sand

-

Rolling shutter door equipment

-

Discharge rack series of hydra

-

Export equipment series

-

Kaiping machine series

-

pipe benders

-

Customize cold bending equipme

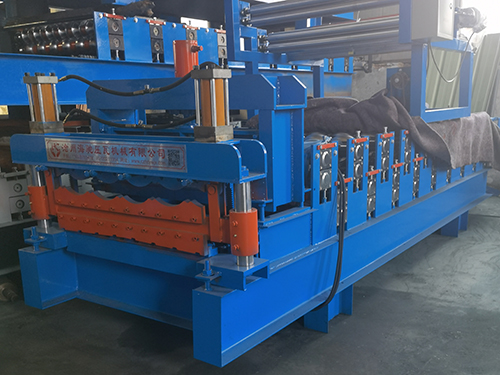

910-828 antique glazed tile equipment tile press

910-828 antique glazed tile equipment tile press adopts a new hydraulic cutting system, which includes forming host, hydraulic station, discharge rack, forming shear, control box, and discharge rack

910-828 antique glazed tile equipment tile press production process: uncoiling - correct feeding into the forming, namely the feeding shaft - measuring length - color plate molding - cut to length - finished product discharge

910-828 antique glazed tile equipment tile press is divided into three parts, roller forming part, molding part and cutter part

910-828 antique glazed tile equipment the forming part of the roller table of the tile press is driven by the motor, and the chain drives each roller to rotate

910-828 antique glazed tile equipment the pressing part of the tile press is a hydraulic cylinder that drives the mold to move up and down, which can press the colored steel into many sections, like glazed tiles

910-828 antique glazed tile equipment the cutting tool of tile press is driven by hydraulic cylinder to move up and down, which can cut off the colored steel tiles

910-828 antique glazed tile equipment tile press production process is as follows: the colored steel plate enters the roller forming part, after forming to the pressing part, it is pressed into equal distance sections, and the cutter is responsible for fixed length cutting. The executive part includes frequency converter drive motor, hydraulic station motor, two hydraulic solenoid valves for pressing, and two hydraulic solenoid valves for cutting knife

the antique glazed tiles formed by 910-828 antique glazed tile equipment tile press rolling die have the characteristics of beautiful appearance, simplicity and elegance, exquisite and unique shape, excellent taste and so on. They can be widely used in garden factories, tourist scenic spots, pavilions, hotels, villas, exhibition halls, resorts, families and other buildings and outdoor decoration

precautions for the use of 910-828 antique glazed tile equipment tile press:

before the use of 910-828 antique glazed tile equipment tile press, check whether the connections are secure, whether the mounting bolts and nuts are tightened, and add enough lubricating oil in the left and right chassis before powering on and starting the machine for commissioning

first, operate the car empty and carefully observe whether there is vibration, noise, whether oil comes from the oil window, whether the movements of various components are coordinated, and then install the mold. When installing the mold, cut off the power supply, manually move the motor belt or big gear, rotate the workbench, and raise the sliding seat to the high point, so that an object can be supported between the workbench and the bottom surface of the sliding seat, so that the anti slip seat will fall naturally, causing an accident

910-828 the mold used by the tile pressing machine of antique glazed tile equipment requires an upper mold and six lower molds of the same specification and size. First install the upper mold and a lower mold, and the lower mold is directly installed on the hexagonal runner workbench. The upper mold is installed on the bottom surface of the sliding seat, and a cushion plate of appropriate thickness is placed. After the upper and lower molds are closed, the clearance around the four edges is uniform, and the distance between the upper and lower molds is equal to the thickness of the required tile blank. Then, the upper mold shall prevail, the workbench shall be rotated, and the remaining five sets of lower molds shall be installed. After all the upper and lower molds are installed, the tile pressing can be started

910-828 antique glazed tile equipment technical parameters of tile press:

overall dimension of feeding rack: 5800mm long × 1350mm wide × 1200mm high

the maximum speed of the forming machine: 10m/min

the thickness of the formed color steel plate: 0.5-0.6mm

the expanded width of the formed color steel plate: 1000mm

the width of the formed glazed tile: 828mm, deviation ± 1/100

the wave height of the formed glazed tile: 28mm, deviation 28-0.3

roll shaft diameter: Φ 70mm

computer operation panel, text screen

press roll material: 45 # steel forging parts

molding machine guide feed rack form: roller type