-

Single layer tile press series

-

Double layer tile press series

-

Three layer tile press series

-

Floor bearing plate equipment

-

Glazed tile equipment series

-

Jiaochi equipment series

-

C/z/u-shaped steel forming mac

-

Carriage plate forming machine

-

Anti skid embossing equipment

-

Aluminum magnesium manganese 4

-

Ridge tile forming machine ser

-

Light steel keel machine serie

-

Shearing machine bending machi

-

Rock wool foam integrated sand

-

Rolling shutter door equipment

-

Discharge rack series of hydra

-

Export equipment series

-

Kaiping machine series

-

pipe benders

-

Customize cold bending equipme

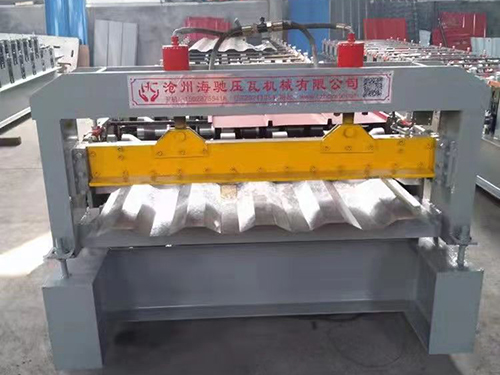

Carriage plate forming machine

The carriage plate forming machine is composed of loading trolley, uncoiler, leveling machine, overturning bracket, feeding guide, roll forming machine, tracking spot welding, finished product straightening, flying saw, telescopic material rack and electrical control system. The carriage plate forming machine is composed of tension uncoiler - leveling equipment - forming host - spot welding machine - PLC computer-controlled flying saw cutting - Product correction - support frame. It is mainly used for the production of side panels, corrugated side panels and integrated side panels of cars, tricycles, trucks and other carriages

the carriage plate forming machine is applicable to the cold bending forming of galvanized or colored steel coils with a width of 0.4-1.5mm and a large width of 1200mm. Typical products include steel structure, decoration, automobile, environmental protection and other industries

car board machine configuration:

uncoiler, leveling machine, servo feeder, punching machine, molding machine, shearer, discharge platform, PLC electrical control system

main structural features of the carriage plate forming machine:

1. The carriage plate forming machine has a beautiful structure. Because the whole machine adopts H-shaped steel structure and is processed as a whole after welding, it has a simple and reasonable structure, good load storage capacity and stable operation

2. Other important parts and components of the carriage plate forming machine are accessories of domestic excellent enterprises, thus determining the performance of the equipment

3. The carriage plate forming machine has high automation, fixed length cutting, accurate fixed length positioning, beautiful and tidy shape head and tail, and no deformation

4. The carriage plate forming machine is easy to install and debug, which is suitable for factory production

5. The car panel forming machine has low noise and good working efficiency

main technical parameters of carriage plate forming machine:

rolling capacity of the unit: width: 400-800mm

plate thickness: 1.0-2.0mm

production speed: 0-15 M / min

total installed capacity: about 35.5kw

production floor area: 18 m long x 3 m wide

voltage: 380v/ 415V, 50Hz, 3 compartment

overall dimension of equipment: about 9500*1600*1500mm

working pressure of hydraulic system: 16MPa

forming shaft: diameter 85mm 45 # quenching and tempering

forming wheel: material 45 # forging and plating hard chromium

transmission mode: 2-inch sprocket Chain

number of forming rows: 11 rows

automatic computer fixed length cutting system:

pump station motor: 3kw four stage

shear mold: Gr12

forming speed: 8-10m/min

pressing thickness: 0.2-0.7mm

pressing width: 1000m

hydraulic system motor power: 4kw

middle plate: 14mm